What is Mini CAT 6 Cable

All right guys, so what’s the biggest challenge in data centers? It’s cable management, right? Isn’t Copper cables makes more trouble than fibers? Especially the rigid, non-flexible, and space consumption than fibers? Oh man, it’s a huge problem. Well, mini CAT6 cables are a simple solution to these challenges with copper cabling. Let’s have a deep dive into the concept of mini CAT6 cables.

The term ‘mini’ refers to the smaller OD(outer diameter), obtained by using 28 AWG(American Wire Gauge) copper conductors, rather than the typical 24 AWG copper conductors used in regular copper cables, thereby reducing the cables outside diameter. Mini CAT6 cables are up to 50% smaller than a standard patch cord(depending on the manufacturer)”. The use of mini patch cords in today’s high-speed networks, provides a number of key operational and performance advantages, especially at workstations and in data racks. When specifying these smaller diameter patch cords, it is important that due consideration is given to the technical differences between mini patch cords and regular diameter patch cords, to ensure that the link performs at its optimum.

Let’s have deep diving into these design specifications, What would be the major change when it comes to mini CAT6 cables than the standard CAT6 cables? Is the number of copper cables or it’s pairs are reduced in mini CAT6? How do they achieve this smaller size? The answers is pretty simple, the advantage of mini CAT6 cables are its AWG(American Wire Gauge) values. That’s American Wire Gauge (AWG) is an index that inversely and logarithmically tells us the thickness of conductive wires or we can say that cable’s gauge indicates the thickness of the conductor in which the electrons flow. The smaller the gauge, the bigger the conductor, but the relationship is logarithmic not linear. For example, a 40-AWG solid wire has a circular mil area, as specified by the National Bureau of Standards, of 9.61, a 30-AWG wire has a circular mil area of 100.5, a 20-AWG wire comes in at 1020, and a 10-AWG at 10380. So to answer our first question, mini CAT6 cables are not reducing the number of copper cables used in design, it still remains 8 copper cables(4 pairs) and the variation is higher AWG values which reduces the thickness of these copper cables used.

*These are what are commonly seen in the industry, however there are variations between manufacturers

** Max length is 90m for the installed cable and 10m for patch cords.

Generally there are 2 types of mini copper cables are available in market,

- Mini CAT6 U/UTP AWG28 – RJ45 unshielded patch cords

- Mini CAT6A U/FTP AWG28 – RJ45 shielded patch cords

Mini CAT6 U/UTP patch cords (CAT6 unshielded patch cords) are more than 55% lighter, 50% smaller in cross-sectional area and provide more than 40% tighter bend radius when compared with standard Category 6 (CAT6) patch cables.

Mini CAT6A U/FTP patch cords (CAT6A shielded patch cords) are approximately 15-20% smaller in diameter and more flexible, when compared with standard Category 6A (CAT6A) patch cables.

Now let’s list out the advantages of mini CAT6 cables over standard CAT6 cables,

Space Saving Design – Reduced Diameter: The smaller cable diameter allows twice the amount of cable to be routed through cable managers and pathways compared to traditional Cat6 patch cables. This saves valuable space in a high density environment.

Improved visibility of port labels on patch panels and other network equipment and these cables makes easier installation in crowded racks.

Improved airflow in high-density rack is one of the other advantage. As you know the reduced diameter of cables can provide you more free space within the cable manager which will also increase the airflow within the racks.

Flexible Cable – Small Bend Radius: Use of UTP stranded 28 AWG copper cable allows for a very flexible patch cable with tight bend radius suitable for high density installations and superior cable management.

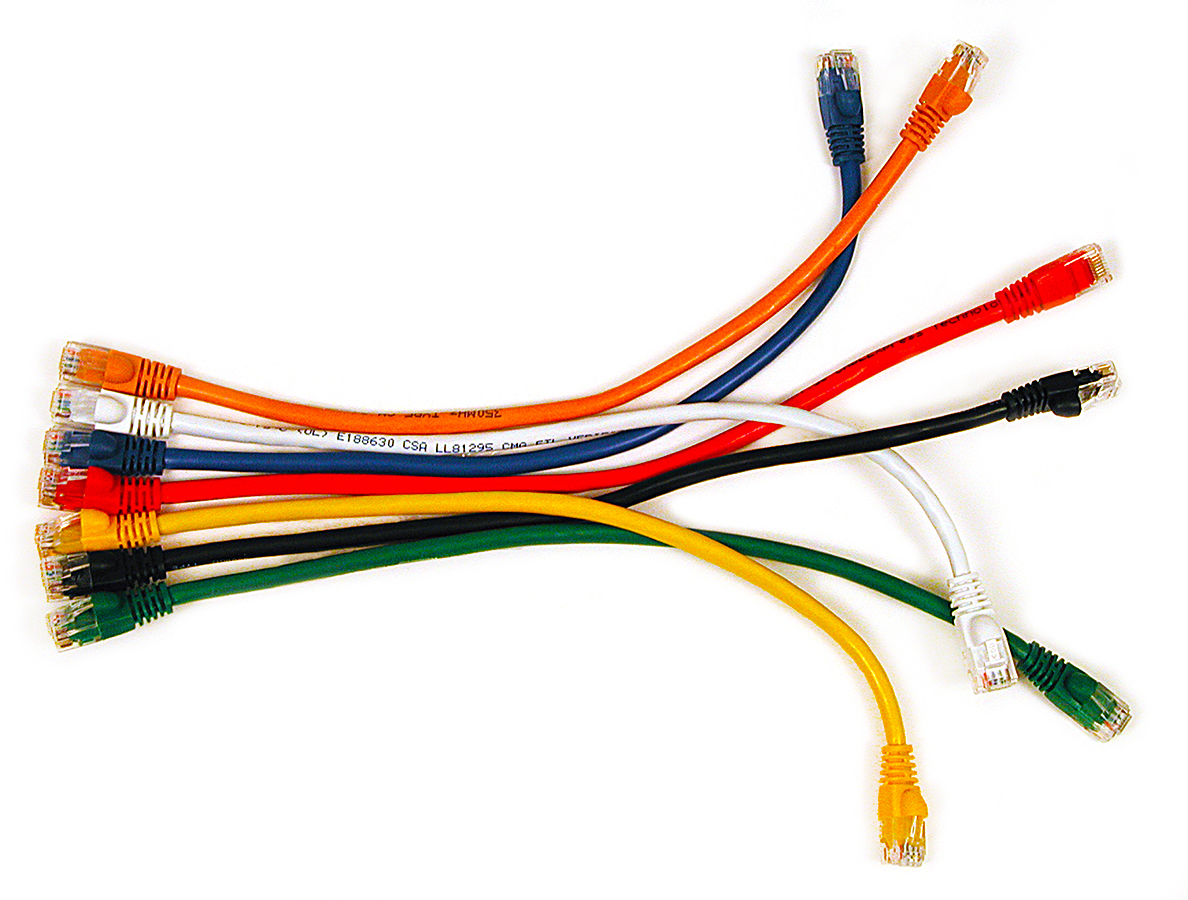

Variety of Colors – The Ultra Slim Cat6 UTP, 28AWG, Network Cables are available in ten colors for your choice.

When considering the greater administration advantages of mini CAT6 cables, have you seen it as widely used? Mostly not, and there a number of drawbacks for this,

Short distance run – The smaller the gauge, the larger the diameter of the wire. The larger the diameter of a wire, the less electrical resistance there is for the signals it carries. Copper network cables with a smaller gauge (larger diameter) are typically available in longer lengths because they offer less resistance, allowing signals to travel farther. Less resistance also generates less heat. A 24 AWG network cable will offer less resistance than a 26 AWG or 28 AWG network cable. So we can say that even these days mini CAT6 cables are used only for patch panel cablings or maximum length is 90m for the installed cable and 10m for patch cords.

Less heat resistance – The same drawback of less electrical resistance is having an effect on POE(Power over ethernet) environment as well. In the cable industry, it is referred to as the current flow (of electrons) that runs throughout the wire. Imagine a flow of water that runs through a pipe. The wider the pipe is, the more water runs through it in a shorter time. How does that translate to cables? Resistance is how many electrons make it through the cable and do not evaporate. With a thinner cable, there is less flow and heat buildup, which causes the electrons to dissipate. The wider the cable, the easier it is for the electrons to pass through it. Hence there are chances that the usage of mini CAT6 cables in higher bundles of POE environment can cause some kind of heat dissipation and increases the chance of burnout. Many of the mini CAT6 cable manufacturers are specify a maximum bundle size of 24 cables to assist in limiting the temperature increases in the cables associated with delivering POE deployments.

What are the differences between the connectors & couplers for standard CAT6 cables and mini Cat6 cables?

With each improvement in technology, going from Cat5E to Cat6 to Cat6A cables, we see better performance. This holds true for the connectors and couplers as well as the cables. So a Cat6 connector will perform better than a Cat5E connector. The same way, you might have leaned now that the copper cables that are inside mini CAT6 cables are smaller than the standard CAT6 cables. If you use higher-grade cables like mini Cat6, you should also use connectors and couplers created for that level of performance.

So what is the suggestion from my side? Mini CAT 6 cables can be used greatly as a replacement for standard CAT6 cables where length is limited to less than 10 meters or patch panel connections. Whereas the standard CAT6 cables would be still the best option for long-distance and POE environments.

Knowledge Credits: Cablexpress

Have a comment or points to be reviewed? Let us grow together. Feel free to comment.